Back to top

About The Group

Our parent company, Shree Bankey Behari Lal Group was started in 1965 by Shri Gopal Narain Gupta. It started with the first unit and named it as Shree Bankey Behari Lal Board Mills to manufacture and meet the market demands for semi kraft paper.

With the passing of time and to grab more opportunities in the industry, by 1995, the group turned the business into a natural Menthol manufacturing unit. Further, with the extensive R&D work, in 2015, the group started manufacturing Thymol from Meta Cresol.

In 2012, the group company launched its first synthetic product - Menthone, Producing 1500 MTPA. (Metric Tons Per Annum) to mark its presence in the mint derivatives market.

About Our Sister Concerns

Quality Assurance

Since inception, we have been delighting customers with our quality assurance process and initiatives. We take the following steps to give that assurance to customers:

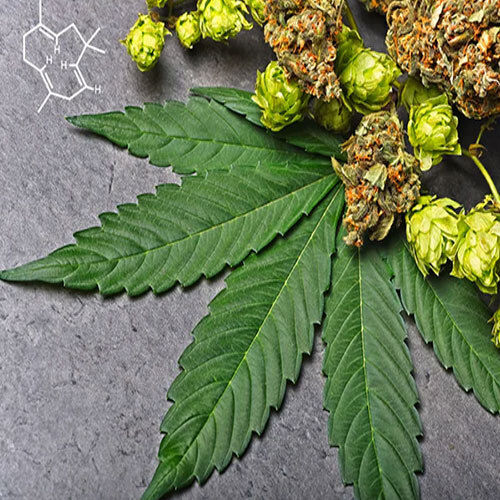

Globally famous for providing high quality L-Carvone Flavor, Thymol Methyl Ether, Alpha Humulene Flavor, Thymol Crystals, Neo Menthol Oil, Mesityl Oxide Solvent, Spearmint Oil, and many other products.

Shree Bankey Behari Lal Group was started in 1965 by Shri Gopal Narain Gupta with the first unit been named Shree Bankey Behari Lal Board Mills which was into manufacturing of Semi Kraft Paper. In 1996, the business activity was changed from manufacturing of Semi-kraft Paper to Natural Menthol. In 2005, manufacturing of Thymol was started from raw material Meta Cresol. Slowly the group transitioned with their strong R&D to be the first manufacturer to offer Racemic Menthone commercially in 2012. Annual capacity of the plant is 1500 Mt.

The second manufacturing unit, Shree Bankey Behari Lal Aromatics was found in 2012 which manufactures L-Carvone, D-Carvone and Carvacrol. The company is also offering niche Carvone, Thymol and Carvacrol derivatives. In addition to this, we are also the only Indian manufacturer to offer Pine Derivatives like Alpha Terpinene, Gamma Terpinene, Terpinolene, P-cymene & Terpinen-4-ol in commercial bulk volumes. Annual capacity of plant is 3000 Mt.

Wanting to cater the mint industry and with highly improved and enhanced techniques the group came up with manufacturing of DL Menthol, L-menthol and Acetone Derivatives.

This new plant Shree Bankey Behari Lal flavors found in 2017 has a capacity of 9000 MTPA combined of both DL & L Menthol Diacetone Alcohol, Mesityl Oxide Hexylene Glycol.

In addition to that this unit is offering cornmint oil according to specifications that is required in different regions with variations in olfactory and contents.

The group has scaled new heights and is now manufacturing over 15000 Mt speciality flavor and fragrance ingredients with more than a doubled digit growth rate for the past 15 years. The company believes in its core value of offer world class products at sustainable and competitive market price.

The second manufacturing unit, Shree Bankey Behari Lal Aromatics was found in 2012 which manufactures L-Carvone, D-Carvone and Carvacrol. The company is also offering niche Carvone, Thymol and Carvacrol derivatives. In addition to this, we are also the only Indian manufacturer to offer Pine Derivatives like Alpha Terpinene, Gamma Terpinene, Terpinolene, P-cymene & Terpinen-4-ol in commercial bulk volumes. Annual capacity of plant is 3000 Mt.

Wanting to cater the mint industry and with highly improved and enhanced techniques the group came up with manufacturing of DL Menthol, L-menthol and Acetone Derivatives.

This new plant Shree Bankey Behari Lal flavors found in 2017 has a capacity of 9000 MTPA combined of both DL & L Menthol Diacetone Alcohol, Mesityl Oxide Hexylene Glycol.

In addition to that this unit is offering cornmint oil according to specifications that is required in different regions with variations in olfactory and contents.

The group has scaled new heights and is now manufacturing over 15000 Mt speciality flavor and fragrance ingredients with more than a doubled digit growth rate for the past 15 years. The company believes in its core value of offer world class products at sustainable and competitive market price.

About The Group

Our parent company, Shree Bankey Behari Lal Group was started in 1965 by Shri Gopal Narain Gupta. It started with the first unit and named it as Shree Bankey Behari Lal Board Mills to manufacture and meet the market demands for semi kraft paper.

With the passing of time and to grab more opportunities in the industry, by 1995, the group turned the business into a natural Menthol manufacturing unit. Further, with the extensive R&D work, in 2015, the group started manufacturing Thymol from Meta Cresol.

In 2012, the group company launched its first synthetic product - Menthone, Producing 1500 MTPA. (Metric Tons Per Annum) to mark its presence in the mint derivatives market.

About Our Sister Concerns

|

Company Name |

Year of Establishment |

Details |

|

Shree Bankey Behari Lal Board Mills |

1965 |

|

|

Shree Bankey Behari Lal Aromatics |

2013 |

|

Quality Assurance

Since inception, we have been delighting customers with our quality assurance process and initiatives. We take the following steps to give that assurance to customers:

- We conduct Raw Material Inspection by examining that the incoming raw materials meet the industry specifications and have the desired consistency and purity.

- We take numerous Process Control measures throughout the manufacturing to maintain consistency and ensure that products are within specified limits.

- We conduct In-process Testing to identify and rectify any deviations on parameters such as monitor reaction kinetics, pressure, temperature, and others.

- We perform Analytical Testing of final products to ensure compliance with the industry specifications. We do this with the use of techniques such as spectroscopy, chromatography, and filtration for accurate results.

- We provide quality assurance to customers by maintaining detailed documentation of our processes and quality control procedures.

- We conduct Batch Sampling and then retain samples for reference and future analysis.

- We focus on regular calibration of production equipment to maintain high level of accuracy.

- We periodically monitor environmental conditions in production space to prevent contamination. We also take measures to control humidity, temperature and many such factors.

- We focus on checking the integrity of the packaging materials and ensuring its compliance with safety standards.

- We also take the required measures for updated right labels and batch codes.

- We conduct a final inspection of finished products and the packaging to ensure perfection.

- We focus on conducting the Stability Testing to ensure our products remain effective and safe throughout their shelf life.

- We conduct audit processes to have compliance of our activities with regulatory requirements.

- We periodically provide training to staff members, who are engaged in the manufacturing and quality control work. We also employ members, who are properly certified and follow Good Manufacturing Practices (GMP).

- We follow an established system for feedback and continuous improvement.

Send Inquiry

Send Inquiry Send SMS

Send SMS